- Home Page

- Company Profile

-

Our Products

- Non Woven Bag Making Machine

- Leader Teach 26 Automatic Non Woven Box Bag Making Machine with Online Handle

- Oyang 19 Automatic Non Woven Box Bag Making Machine with Handle Online

- Oyang 18 Automatic Non Woven Leader Box Bag Making Machine with Handle Online

- Oyang 16S Automatic Non Woven Box Bag Making Machine with Handle Online

- XC700-800 Automatic Non Woven 3 in 1 Bag Making Machine with Handle Online

- B700-800 Automatic Non Woven 5 in 1 Bag Making Machine without Handle

- TYM1300 Non Woven Hot Foil Roll to Roll Stamping Machine

- OYANG16 M1100-1800 High Speed Coating and Lamination Machine

- Paper Bag Making Machine

- TECH 18 400S Intelligent Bag Making Machine with Twisted Handle

- High Speed Fix Size Paper Bag Machine

- Automatic Roll-fed Twist Rope Paper Bag Machine Series (with Online Handle)

- Semi-Automatic Roll-fed Paper Bag Machine (Without Handle)

- Roll-fed Sharp Bottom Paper Bag Machine (V-Bottom)

- ONL-SL Slitting Machine

- Automatic Flat Paper Handle Pasting Machine

- Automatic Round Rope Paper Handle Pasting Machine

- Double Station Twisted Paper Rope Machine

- Paper Rope Rewinding Machine

- Flexographic Printing Machine

- Rotogravure Printing Machine

- Screen Printing Machine

- Non Woven Bag Making Machine

- Contact Us

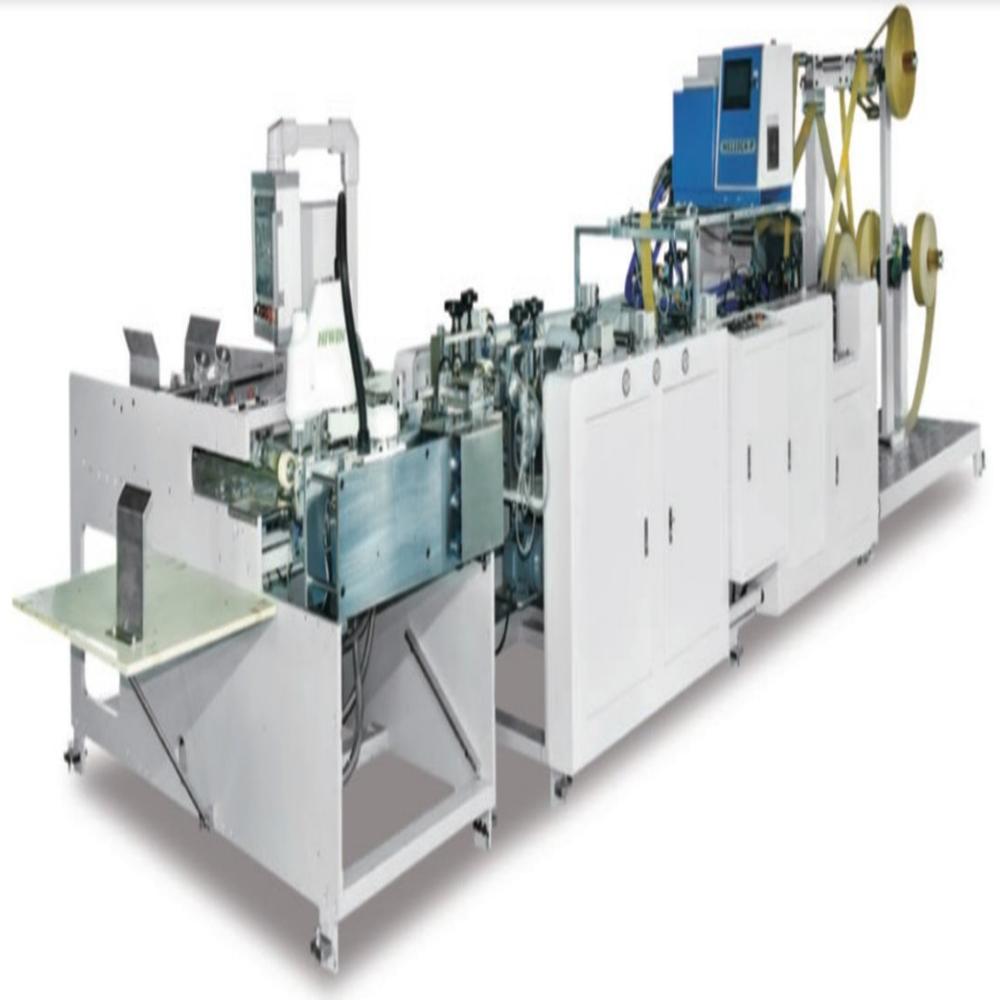

Paper Rope Rewinding Machine

180000.0 INR/Piece

Product Details:

- Product Type paper bag

- General Use paper bag

- Efficiency 380V

- Weight (kg) 200 Kilograms (kg)

- Automatic Grade Semi Automatic

- Drive Type Electric

- Bag Type Paper Bag

- Click to view more

X

Paper Rope Rewinding Machine Price And Quantity

- 180000.0 INR/Piece

- 1 Piece

Paper Rope Rewinding Machine Product Specifications

- white & blue

- 380v Volt (v)

- 1 Year

- Yes

- paper bag

- 200 Kilograms (kg)

- 380 Volt (v)

- Paper

- 600 Millimeter (mm)

- paper bag

- 380V

- 4x2.5x6 Foot (ft)

- Paper Bag

- Electric

- No

- Many Features

- Semi Automatic

Paper Rope Rewinding Machine Trade Information

- 40 Days

Product Description

Key Functional Features

High-speed rewinding: Converts many small twisted paper rope rolls into one large roll to support continuous automatic processes.

Improved productivity: Larger and smoother rope reels reduce changeovers and stoppage in downstream equipment.

Automatic stop/count functions: Some models include length-counting and auto-stop features.

| Specification | Typical Value / Range |

|---|---|

| Machine Type | Paper Rope Rewinding Machine (ONL-RE / similar models) |

| Application | Rewinds small twisted paper rope rolls into large uniform rolls for continuous feed into handle making or bag systems. |

| Core (Raw Rope) Diameter | 76 mm (standard) |

| Core (Final Rope) Diameter | 180 mm typical (optionally configurable) |

| Finished Roll Outer Diameter | 400 600 mm (machine-dependent) |

| Maximum Production Speed | 80 150 m/min (typical) |

| Voltage | 380 V, 3-Phase, 50 Hz (most industrial models) |

| Total Power | ~2.2 kW (typical electric motor) |

| Control | Manual start/stop; many models include auto stop after set length (optional) |

| Machine Weight | ~150 kg () |

| Machine Dimensions | ~1050 800 1200 mm (LWH) |

| Features | Avoids rope knotting Stable operation Simple to operate |

Efficient Paper Rope Rewinding Solution

This machine streamlines the rope rewinding process for paper bag production, ensuring swift and uniform results. The semi-automatic operation, combined with computerized controls, allows users to achieve enhanced productivity while minimizing operational errors. Its robust construction supports continuous industrial usage.

Designed for Versatility and Durability

Engineered to accommodate paper ropes for bags measuring up to 600 mm, this machine fits the needs of various paper bag manufacturers. Manufactured in India, it combines a sturdy design with high-performance features, suitable for demanding production settings. The electric drive ensures stable, consistent performance.

FAQ's of Paper Rope Rewinding Machine:

Q: How does the Paper Rope Rewinding Machine operate?

A: The machine runs on a semi-automatic system with computerized controls. Operators can easily set parameters, and the electric drive swiftly rewinds paper ropes, ensuring uniformity and efficiency through the entire process.Q: What is the primary usage of this machine?

A: It is primarily used to rewind paper ropes, which are then utilized for making paper bags. The machine supports bag lengths of up to 600 millimeters and is ideal for manufacturers requiring consistent, high-quality paper rope output.Q: When should maintenance be performed on this machine?

A: Regular maintenance should be performed as indicated in the user manual, typically after specified operational hours or at least once every few months to ensure sustained performance and to comply with the warranty requirements.Q: Where is the Paper Rope Rewinding Machine manufactured and supplied?

A: The machine is manufactured and supplied in India, ensuring easy access to service support and spare parts within the region.Q: What are the benefits of using a computerized semi-automatic rewinding system?

A: Combining computerized control with semi-automatic function reduces manual errors, increases productivity, and offers greater control over the rewinding process, ensuring optimal quality of the final product.Q: What features distinguish this machine from others in the market?

A: This model offers high working efficiency at 380V, robust construction weighing 200 kg, flexibility for different paper bag sizes, and is equipped with a reliable electric drive. Its white and blue finish also provides a modern industrial look.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese