- Home Page

- Company Profile

-

Our Products

- Non Woven Bag Making Machine

- Leader Teach 26 Automatic Non Woven Box Bag Making Machine with Online Handle

- Oyang 19 Automatic Non Woven Box Bag Making Machine with Handle Online

- Oyang 18 Automatic Non Woven Leader Box Bag Making Machine with Handle Online

- Oyang 16S Automatic Non Woven Box Bag Making Machine with Handle Online

- XC700-800 Automatic Non Woven 3 in 1 Bag Making Machine with Handle Online

- B700-800 Automatic Non Woven 5 in 1 Bag Making Machine without Handle

- TYM1300 Non Woven Hot Foil Roll to Roll Stamping Machine

- OYANG16 M1100-1800 High Speed Coating and Lamination Machine

- Paper Bag Making Machine

- TECH 18 400S Intelligent Bag Making Machine with Twisted Handle

- High Speed Fix Size Paper Bag Machine

- Automatic Roll-fed Twist Rope Paper Bag Machine Series (with Online Handle)

- Semi-Automatic Roll-fed Paper Bag Machine (Without Handle)

- Roll-fed Sharp Bottom Paper Bag Machine (V-Bottom)

- ONL-SL Slitting Machine

- Automatic Flat Paper Handle Pasting Machine

- Automatic Round Rope Paper Handle Pasting Machine

- Double Station Twisted Paper Rope Machine

- Paper Rope Rewinding Machine

- Flexographic Printing Machine

- Rotogravure Printing Machine

- Screen Printing Machine

- Non Woven Bag Making Machine

- Contact Us

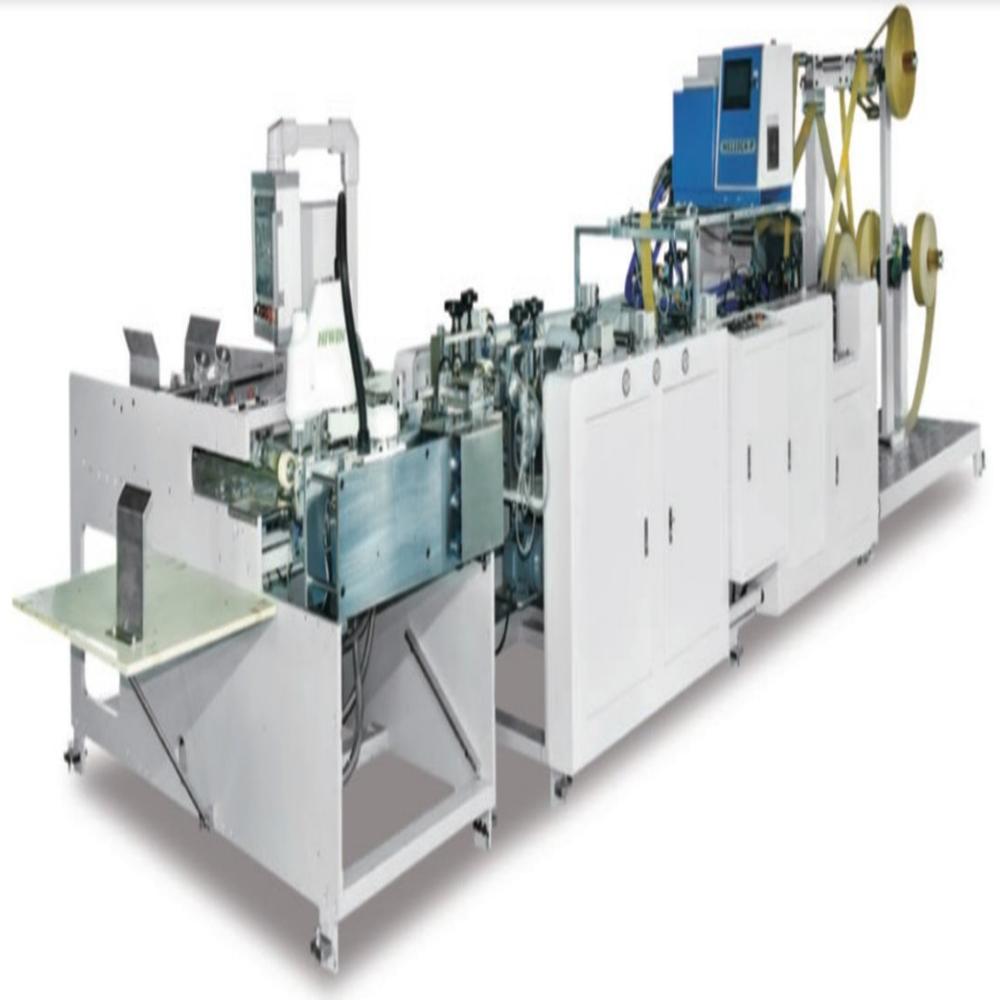

Roll-fed Sharp Bottom Paper Bag Machine (V-Bottom)

5500000.0 INR/Piece

Product Details:

- Product Type Paper Bag

- General Use Paper Bag

- Weight (kg) 5000 Kilograms (kg)

- Automatic Grade Automatic

- Drive Type Electric

- Bag Type Flat Bags

- Computerized Yes

- Click to view more

X

Roll-fed Sharp Bottom Paper Bag Machine (V-Bottom) Price And Quantity

- 1 Piece

- 5500000.0 INR/Piece

Roll-fed Sharp Bottom Paper Bag Machine (V-Bottom) Product Specifications

- 1 Year

- 400 Millimeter (mm)

- 380 Volt (v)

- Paper Bag

- Automatic

- 5000 Kilograms (kg)

- Paper

- 380 Volt (v)

- Yes

- Flat Bags

- Yes

- 7300x2000x1900 Millimeter (mm)

- Electric

- Paper Bag

Roll-fed Sharp Bottom Paper Bag Machine (V-Bottom) Trade Information

- Cheque

- 1 Piece Per Day

- 60 Days

- No

- Container

- All India

Product Description

A RollFed Sharp Bottom Paper Bag Machine is an automatic paper bag making machine that continuously feeds paper from a jumbo roll and forms it into bags with a Vshaped (sharp) bottom a style especially popular for snacks, food packaging, bakery goods, grocery paper bags, and ecofriendly retail bags.

These machines integrate the entire workflow feeding, gluing, perforating, tube forming, cutting, bottom folding, and bottom gluing in one automated line to dramatically reduce labor cost and increase output.

| Specification | C270 | C330 |

|---|---|---|

| Paper Thickness Range | 30100gsm | 30100gsm |

| Bag Width (W) | 80270mm | 80350mm |

| Bag Length (L) | 120400mm | 120720mm |

| Side Folding Range | 060mm | 060mm |

| Production Precision | 0.2mm | 0.2mm |

| Machine Speed | 150500pcs/min | 150500pcs/min |

| Max Paper Roll Width | 900mm | 1000mm |

| Max Roll Diameter | 1200mm | 1200mm |

| Total Power | ~16kW | ~16kW |

| Machine Weight | ~5000kg | ~5500kg |

| Machine Size (LWH) | ~730020001850mm | ~770020001900mm |

High-Efficiency Automatic Paper Bag Production

Engineered for speed and precision, this roll-fed machine automates the process of crafting V-bottom, sharp-bottom paper bags. Its computerized controls and photoelectric correction ensure that every produced bag conforms to exact specifications, boosting productivity and minimizing errors.

Robust Design for Industrial Environments

This machine's sturdy 5000 kg structure and sizeable footprint allow for continuous, long-term operation. Designed to handle intensive workloads, it is an excellent choice for manufacturers looking for reliable equipment to meet growing demands in the paper bag industry.

User-Friendly with Advanced Features

Operating with a 380V electric drive and a fully computerized interface, this machine is both powerful and easy to use. Routine maintenance is simplified by intelligent design and a comprehensive one-year warranty, providing peace of mind and steady performance.

FAQ's of Roll-fed Sharp Bottom Paper Bag Machine (V-Bottom):

Q: How does the Roll-fed Sharp Bottom Paper Bag Machine (V-Bottom) operate?

A: This machine automatically converts rolls of paper into sharp-bottom, flat bags through a sequence of unwinding, folding, gluing, shaping, and cutting, all managed by computerized controls for precision.Q: What types of paper bags can this machine produce?

A: It is designed to manufacture flat, V-bottom sharp-bottom paper bags with lengths up to 400 mm, suitable for a broad range of general paper bag applications.Q: Where is this machine commonly used?

A: The machine is most often used by paper bag manufacturers and suppliers in industrial settings across India, particularly where large-scale, automated production is required.Q: What are the key benefits of using this paper bag machine?

A: Benefits include high production efficiency, consistent bag quality, reduced manual intervention, decreased error rates due to photoelectric correction, and user-friendly operation.Q: When should routine maintenance be performed on this machine?

A: Routine maintenance should be carried out according to the manufacturer's recommendations, typically after set operating hours or production cycles, to ensure optimal performance and longevity.Q: What is included in the 1-year warranty?

A: The 1-year warranty generally covers manufacturing defects and certain mechanical or electrical failures under normal operating conditions, offering reliable support to users.Q: How does the photoelectric correction system improve the production process?

A: The photoelectric correction system continuously monitors and adjusts the paper feed, ensuring bags are cut and formed precisely, which reduces wastage and improves overall quality.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese