- Home Page

- Company Profile

-

Our Products

- Non Woven Bag Making Machine

- Leader Teach 26 Automatic Non Woven Box Bag Making Machine with Online Handle

- Oyang 19 Automatic Non Woven Box Bag Making Machine with Handle Online

- Oyang 18 Automatic Non Woven Leader Box Bag Making Machine with Handle Online

- Oyang 16S Automatic Non Woven Box Bag Making Machine with Handle Online

- XC700-800 Automatic Non Woven 3 in 1 Bag Making Machine with Handle Online

- B700-800 Automatic Non Woven 5 in 1 Bag Making Machine without Handle

- TYM1300 Non Woven Hot Foil Roll to Roll Stamping Machine

- OYANG16 M1100-1800 High Speed Coating and Lamination Machine

- Paper Bag Making Machine

- TECH 18 400S Intelligent Bag Making Machine with Twisted Handle

- High Speed Fix Size Paper Bag Machine

- Automatic Roll-fed Twist Rope Paper Bag Machine Series (with Online Handle)

- Semi-Automatic Roll-fed Paper Bag Machine (Without Handle)

- Roll-fed Sharp Bottom Paper Bag Machine (V-Bottom)

- ONL-SL Slitting Machine

- Automatic Flat Paper Handle Pasting Machine

- Automatic Round Rope Paper Handle Pasting Machine

- Double Station Twisted Paper Rope Machine

- Paper Rope Rewinding Machine

- Flexographic Printing Machine

- Rotogravure Printing Machine

- Screen Printing Machine

- Non Woven Bag Making Machine

- Contact Us

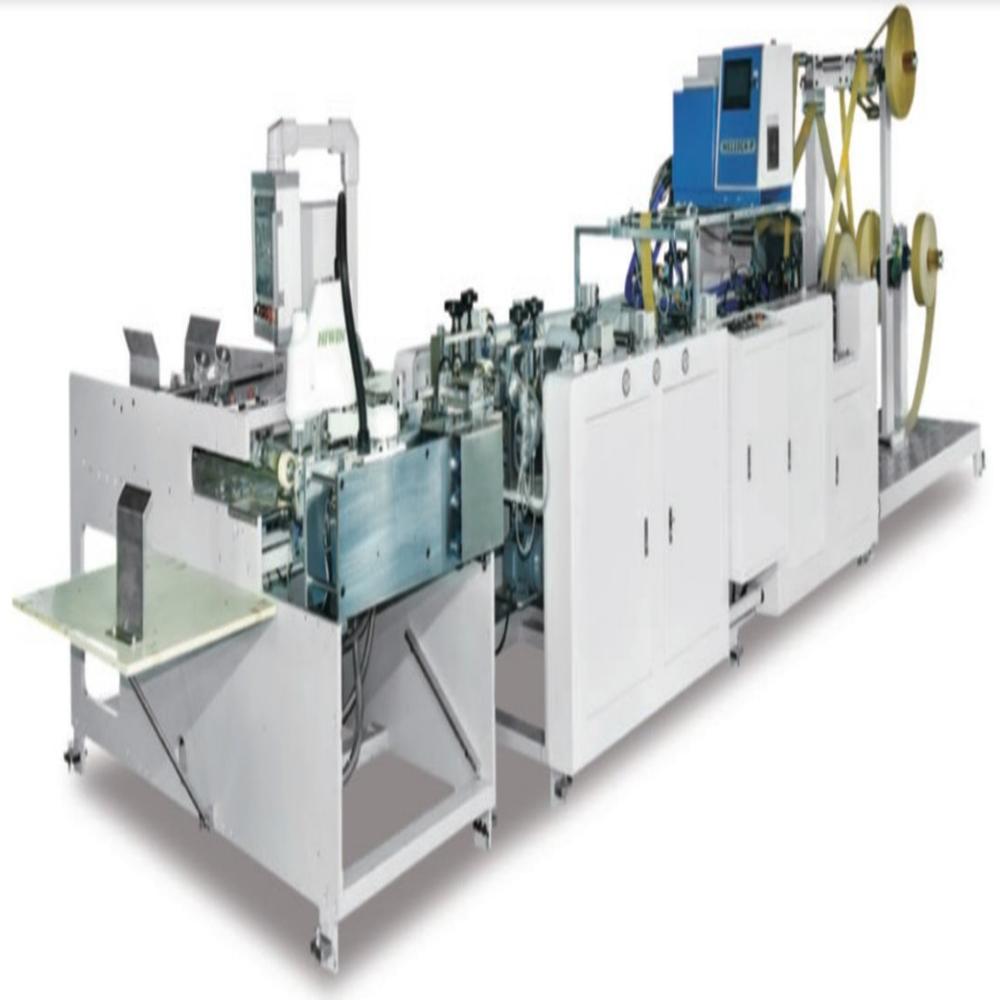

Automatic Roll-fed Twist Rope Paper Bag Machine Series (with Online Handle)

15500000.0 INR/Unit

Product Details:

- Product Type Paper Bag

- General Use Paper Bag

- Weight (kg) 18000 Kilograms (kg)

- Automatic Grade Automatic

- Drive Type Electric

- Bag Type Shopping Bag

- Computerized Yes

- Click to view more

X

Automatic Roll-fed Twist Rope Paper Bag Machine Series (with Online Handle) Price And Quantity

- 1 Piece

- 15500000.0 INR/Unit

Automatic Roll-fed Twist Rope Paper Bag Machine Series (with Online Handle) Product Specifications

- 550 Millimeter (mm)

- Yes

- 380 Volt (v)

- Automatic

- 15x6x3.5 Meter (m)

- Paper Bag

- 380 Volt (v)

- Paper

- 1 Year

- Yes

- Shopping Bag

- 18000 Kilograms (kg)

- Electric

- Paper Bag

Automatic Roll-fed Twist Rope Paper Bag Machine Series (with Online Handle) Trade Information

- Cheque

- 1 Piece Per Month

- 60 Days

- No

- Free samples are available

- Continer

- All India

Product Description

The OYANG Automatic Rollfed Twist Rope Paper Bag Machine Series (often referred to as the SMART17 Series) is a fully automatic, servocontrolled paper bag production machine that takes:

-

Paper roll stock

-

Patch paper roll (for handle reinforcement)

-

Paper rope (for twisted handles)

and transforms them into finished paper bags with twisted rope handles through a fully integrated workflow.

This machine is widely used by manufacturers of shopping bags, clothing and gift packaging bags, boutique paper bags, and branded retail packaging. Its designed to minimize labor, increase production efficiency, and deliver consistent quality with precise dimensions and strong handle attachment.

Advanced Automation for Modern Bag Production

This machine series features comprehensive automation with a computerized interface, ensuring high efficiency and minimal operator intervention. The integrated online handle system enables the twisted rope handles to be attached seamlessly during production, optimizing both speed and quality. The photoelectric correction system guarantees precise paper alignment, reducing waste and enhancing bag consistency for demanding commercial applications.

Durable Design Meets High Performance

Built with durability in mind, the Automatic Roll-fed Twist Rope Paper Bag Machine specializes in long-term industrial use. Its electric drive and robust 18,000 kg construction ensure stable operation and longevity. Operating at a standardized 380 volt power supply, the machine is suitable for large manufacturing environments where continuous performance and reliability are essential for high-output needs.

FAQ's of Automatic Roll-fed Twist Rope Paper Bag Machine Series (with Online Handle):

Q: How does the online handle system work in this paper bag machine series?

A: The machine features an integrated online handle system that automatically forms and attaches twisted rope handles to the bags during production, eliminating the need for manual handle addition and ensuring consistent placement on each shopping bag.Q: What types of bags can be produced with this machine?

A: This series is designed specifically for creating paper shopping bags with twisted rope handles, suitable for retail, boutiques, and promotional applications. The machine accommodates bag lengths up to 550 mm, catering to various bag sizes.Q: When is it recommended to use photoelectric correction during production?

A: Photoelectric correction is a standard feature on this machine and should be used throughout the production process to maintain accurate paper alignment, minimize material waste, and ensure each paper bag maintains proper shape and appearance.Q: Where is this machine typically installed and operated?

A: Given its size (15x6x3.5 meters) and weight (18,000 kg), this automated machine is typically installed in large industrial or manufacturing facilities, making it ideal for businesses in India engaged in medium to high-volume bag production.Q: What is the primary benefit of using an automatic grade machine for paper bags?

A: The automatic grade feature streamlines the entire bag manufacturing process, increasing speed, reducing labor costs, and ensuring uniform quality across large production runs.Q: How does computerization enhance the operation of this paper bag machine?

A: The advanced computerized system allows for precise control over bag dimensions, handle placement, and overall machine performance. This increases operational efficiency, reduces setup time, and minimizes errors during production.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Call Me Free

Call Me Free