- Home Page

- Company Profile

-

Our Products

- Non Woven Bag Making Machine

- Leader Teach 26 Automatic Non Woven Box Bag Making Machine with Online Handle

- Oyang 19 Automatic Non Woven Box Bag Making Machine with Handle Online

- Oyang 18 Automatic Non Woven Leader Box Bag Making Machine with Handle Online

- Oyang 16S Automatic Non Woven Box Bag Making Machine with Handle Online

- XC700-800 Automatic Non Woven 3 in 1 Bag Making Machine with Handle Online

- B700-800 Automatic Non Woven 5 in 1 Bag Making Machine without Handle

- TYM1300 Non Woven Hot Foil Roll to Roll Stamping Machine

- OYANG16 M1100-1800 High Speed Coating and Lamination Machine

- Paper Bag Making Machine

- TECH 18 400S Intelligent Bag Making Machine with Twisted Handle

- High Speed Fix Size Paper Bag Machine

- Automatic Roll-fed Twist Rope Paper Bag Machine Series (with Online Handle)

- Semi-Automatic Roll-fed Paper Bag Machine (Without Handle)

- Roll-fed Sharp Bottom Paper Bag Machine (V-Bottom)

- ONL-SL Slitting Machine

- Automatic Flat Paper Handle Pasting Machine

- Automatic Round Rope Paper Handle Pasting Machine

- Double Station Twisted Paper Rope Machine

- Paper Rope Rewinding Machine

- Flexographic Printing Machine

- Rotogravure Printing Machine

- Screen Printing Machine

- Non Woven Bag Making Machine

- Contact Us

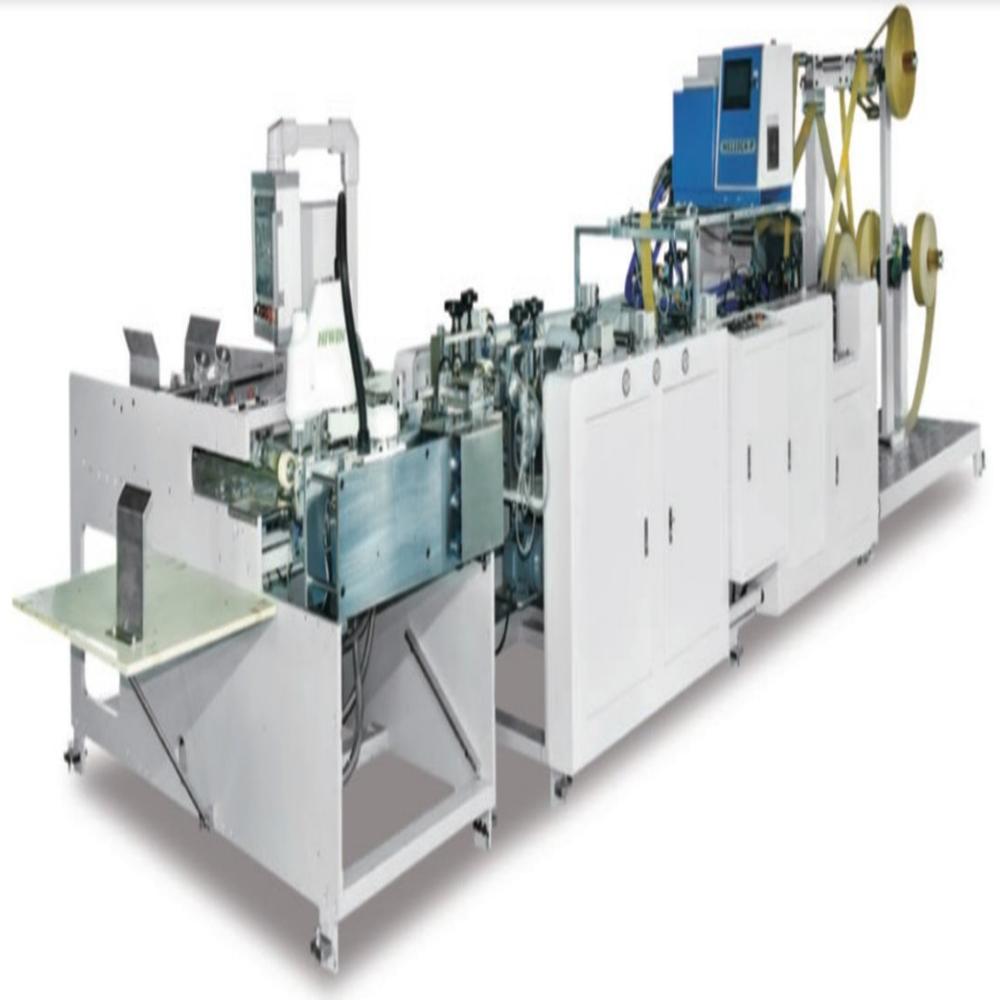

TECH 18 400S Intelligent Bag Making Machine with Twisted Handle

18500000.0 INR/Piece

Product Details:

- Product Type Paper Bag Manufacturer

- General Use Bag Making

- Weight (kg) 18000 Kilograms (kg)

- Automatic Grade Automatic

- Drive Type Electric

- Bag Type Paper Bag

- Computerized Yes

- Click to view more

X

TECH 18 400S Intelligent Bag Making Machine with Twisted Handle Price And Quantity

- 1 Piece

- 18500000.0 INR/Piece

TECH 18 400S Intelligent Bag Making Machine with Twisted Handle Product Specifications

- Paper

- 380 Volt (v)

- Paper Bag

- Paper Bag Manufacturer

- 18000 Kilograms (kg)

- 1 year

- 650 Millimeter (mm)

- 380 Volt (v)

- 49x20x11.5 Foot (ft)

- Yes

- Electric

- Yes

- Bag Making

- Automatic

TECH 18 400S Intelligent Bag Making Machine with Twisted Handle Trade Information

- yes

- Cheque

- 1 Piece Per Day

- 60 Days

- Free samples are available

- container packing

- All India

Product Description

Fully Integrated Production Line

This model integrates multiple processes inline: paper feeding, twisted handle production, handle attachment, tube forming, bottom forming, bag cutting, and stacking delivering end-to-end automation without manual intervention.

High Precision & Fast Changeover

-

Servo-controlled motion for 0.5 mm alignment accuracy.

-

Quick size change bag size adjustment typically done in 15 min.

Advanced Automation

-

PLC + servo system ensures synchronized handle making and bag forming.

-

Reduces labor and improves output consistency.

-

Optional digital printing unit, inline QC, and auto-packing units available.

Versatile Output

-

Ideal for shopping, gift, retail, and food packaging handle bags.

-

Handles a wide range of paper bag sizes with handle integration.

| Handle Feature | Parameters |

|---|---|

| Handle Model | 5HD |

| Handle Height | 95 115 mm |

| Patch Width | 45 50 mm |

| Patch Length | ~152.4 mm |

| Rope Diameter | 4 6 mm |

| Patch Paper Roll Diameter | 1200 mm |

| Patch Roll Width | 90 100 mm |

| Patch Paper Weight | 100 140 g |

| Handle Pitch (Distance) | 76 mm |

Sophisticated Intelligent Automation

The TECH 18 400S machine is equipped with an advanced computerized system, automating every phase of the paper bag making process. This automatic grade technology ensures consistent results, reduces labor interventions, and boosts productivity, making it an excellent asset for modern bag manufacturing facilities.

Robust Construction for High-Capacity Production

With a durable structure weighing 18,000 kilograms, the TECH 18 400S is built to withstand continuous operation and large workloads. Its dimensions of 49x20x11.5 ft allow for the accommodation of high-volume orders while maintaining stability and reliability throughout extensive bag making cycles.

Enhanced Precision with Photoelectric Correction

The integrated photoelectric correction system meticulously monitors alignment and placement, minimizing errors during production. This feature significantly improves product quality, reduces material waste, and ensures each paper bag meets stringent accuracy standards.

FAQ's of TECH 18 400S Intelligent Bag Making Machine with Twisted Handle:

Q: How does the TECH 18 400S ensure precise bag making with twisted handles?

A: The TECH 18 400S uses a computerized system and photoelectric correction to monitor and adjust each step of the process in real-time, resulting in accurately produced paper bags with consistently aligned twisted handles.Q: What type of bags can this machine produce and what materials does it support?

A: This machine is designed specifically for manufacturing paper bags with twisted handles, using paper as the primary material to create eco-friendly, durable, and versatile bags suitable for a range of industries.Q: When is it advisable to use the TECH 18 400S in a manufacturing setup?

A: The TECH 18 400S is ideal for use in high-demand production environments where automated, large-scale, and precisely crafted paper bags are required, particularly when quick turnaround and high consistency are priorities.Q: Where is the TECH 18 400S primarily manufactured and supplied from?

A: The machine is manufactured and supplied from China, making it an accessible solution for companies in the global and regional supply chains seeking reliable bag making technology.Q: What is the process involved in making bags on this machine?

A: The process starts with paper feeding, followed by precision cutting, folding, side gluing, bottom formation, and the automated addition of twisted handles, all managed by its computerized control system for seamless automation.Q: How is the machine powered and what are its dimensional requirements?

A: The TECH 18 400S is powered via a 380 Volt electric drive and requires an installation space accommodating its 49x20x11.5 foot dimensions to ensure optimal operation and maintenance access.Q: What benefits does the 1-year warranty provide to new users?

A: The 1-year warranty assures users of manufacturer support against defects or issues, offering peace of mind and reducing potential operational risks within the initial period of operation.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese