- Home Page

- Company Profile

-

Our Products

- Non Woven Bag Making Machine

- Leader Teach 26 Automatic Non Woven Box Bag Making Machine with Online Handle

- Oyang 19 Automatic Non Woven Box Bag Making Machine with Handle Online

- Oyang 18 Automatic Non Woven Leader Box Bag Making Machine with Handle Online

- Oyang 16S Automatic Non Woven Box Bag Making Machine with Handle Online

- XC700-800 Automatic Non Woven 3 in 1 Bag Making Machine with Handle Online

- B700-800 Automatic Non Woven 5 in 1 Bag Making Machine without Handle

- TYM1300 Non Woven Hot Foil Roll to Roll Stamping Machine

- OYANG16 M1100-1800 High Speed Coating and Lamination Machine

- Paper Bag Making Machine

- TECH 18 400S Intelligent Bag Making Machine with Twisted Handle

- High Speed Fix Size Paper Bag Machine

- Automatic Roll-fed Twist Rope Paper Bag Machine Series (with Online Handle)

- Semi-Automatic Roll-fed Paper Bag Machine (Without Handle)

- Roll-fed Sharp Bottom Paper Bag Machine (V-Bottom)

- ONL-SL Slitting Machine

- Automatic Flat Paper Handle Pasting Machine

- Automatic Round Rope Paper Handle Pasting Machine

- Double Station Twisted Paper Rope Machine

- Paper Rope Rewinding Machine

- Flexographic Printing Machine

- Rotogravure Printing Machine

- Screen Printing Machine

- Non Woven Bag Making Machine

- Contact Us

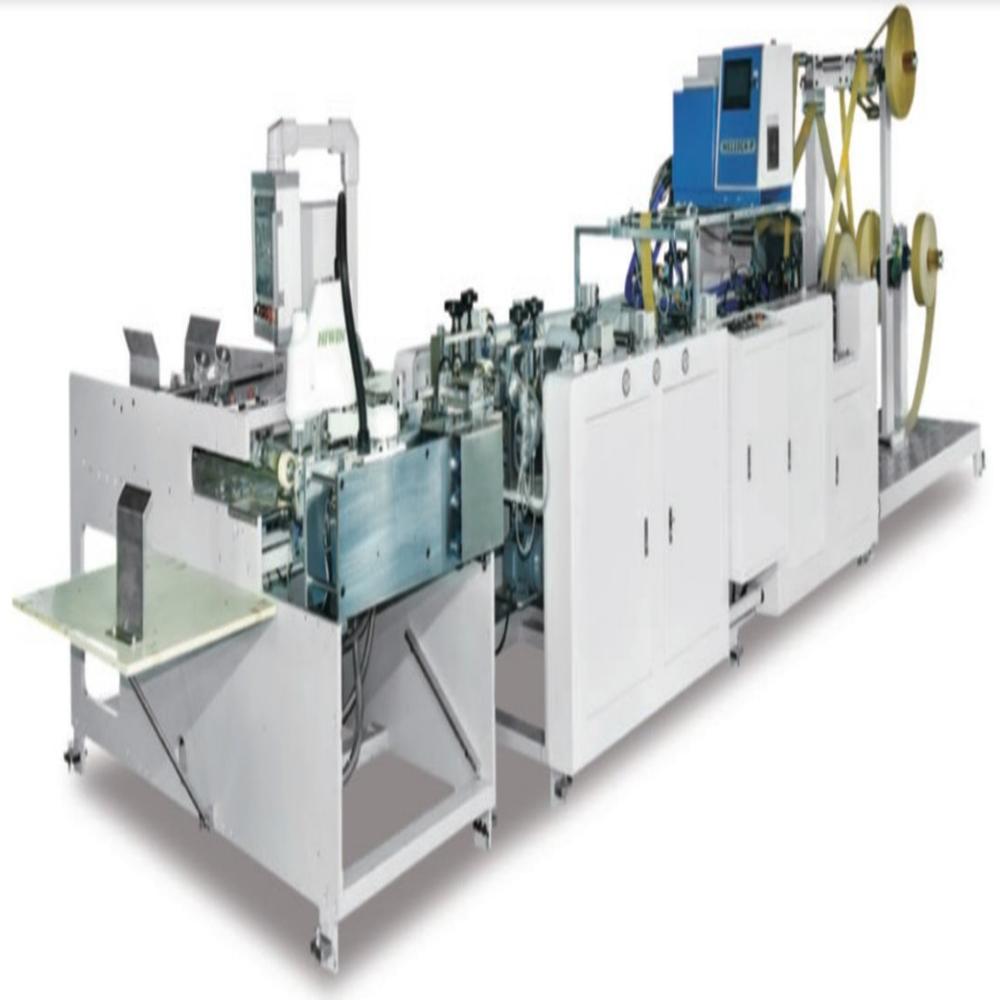

ONL-SL Slitting Machine

225000.0 INR/Unit

Product Details:

- Product Type Paper Bag Sliting Machine

- General Use roll slit

- Weight (kg) 4000 Kilograms (kg)

- Automatic Grade Automatic

- Drive Type Electric

- Bag Type Soft Loop Handle Bag

- Computerized Yes

- Click to view more

X

ONL-SL Slitting Machine Price And Quantity

- 225000.0 INR/Unit

- 1 Piece

ONL-SL Slitting Machine Product Specifications

- Paper

- 4000 Kilograms (kg)

- Paper Bag Sliting Machine

- Yes

- Electric

- Automatic

- Soft Loop Handle Bag

- 11x10.5x6.5 Foot (ft)

- roll slit

- 380 Volt (v)

- Yes

- 1 Year

- 380 Volt (v)

- 63 Inch (in)

ONL-SL Slitting Machine Trade Information

- 40 Days

Product Description

An ONL-SL Slitting Machine is part of Oyangs auxiliary converting equipment designed for slitting wide jumbo rolls into narrow rolls of paper, film, lamination or packaging substrates with precision, especially for printing, bag production, and roll-to-roll converting workflows.| Feature | Typical Specification Range |

|---|---|

| Machine Type | Automatic Slitting & Rewinding Machine |

| Model | ONL-SL Series (Oyang/Allwell conversion slitter) |

| Material Compatibility | Paper, coated paper, craft paper, laminated films |

| Max Mother Roll Width | ~1100 mm / 1300 mm / 1600 mm (configurable) |

| Minimum Slit Width | ~30 mm (depends on setup) |

| Max Mother Roll Diameter | ~1400 mm |

| Max Rewinding Roll Diameter | ~1000 mm |

| Material GSM Range | ~40350 gsm (paper/film conversion range) |

| Slitting Speed | ~10350 m/min (depending on material & setup) |

| Control System | PLC with servo / frequency converter speed control |

| Tension Control | Automatic tension system, edge position correction (EPC |

Precision Slitting for Modern Packaging

Engineered for efficiency, the ONL-SL Slitting Machine excels at transforming paper rolls into perfectly sized soft loop handle bags. Its computerized and photoelectrically corrected operations ensure each cut meets exact specifications, significantly reducing waste and manual error. Suitable for various production environments, this machine guarantees consistent quality and productivity.

User-Friendly and Automated Operations

Designed with convenience in mind, the ONL-SL Slitting Machine boasts an automatic grade system and intuitive computerized controls. Operators benefit from reduced setup times and minimal intervention, allowing for streamlined workflow and decreased labor costs. The electric drive and robust build enable sustained operation with minimal downtime.

FAQ's of ONL-SL Slitting Machine:

Q: How does the ONL-SL Slitting Machine achieve accurate slitting and bag cutting?

A: The ONL-SL Slitting Machine uses photoelectric correction technology and computerized controls to ensure precise cutting and consistent bag lengths up to 63 inches. This guarantees reliable results every cycle.Q: What materials and types of bags is the machine compatible with?

A: The machine is specifically tailored for processing paper rolls and is optimized for producing soft loop handle bags through efficient, automatic slitting.Q: When should maintenance be performed on the slitting machine?

A: It is advised to conduct routine maintenance as per the manufacturer's guidelines, typically after a set number of operational hours or whenever production shifts, to ensure lasting performance. The 1-year warranty also covers most standard repairs.Q: Where can the ONL-SL Slitting Machine be installed?

A: With dimensions of 11x10.5x6.5 feet and a weight of 4000 kg, the machine is suitable for installation in industrial manufacturing facilities with access to a 380 Volt power supply.Q: What is the process of operating this slitting machine?

A: Operation involves feeding paper rolls into the machine, configuring the bag length and specifications through the computerized system, and allowing the automated process to slit and finish each bag with high precision.Q: How does using this machine benefit manufacturing processes?

A: Employing the ONL-SL Slitting Machine enhances productivity through automation, reduces material waste with precise cuts, and lowers labor requirements, all while ensuring consistently high-quality finished bags.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Call Me Free

Call Me Free