- Home Page

- Company Profile

-

Our Products

- Non Woven Bag Making Machine

- Leader Teach 26 Automatic Non Woven Box Bag Making Machine with Online Handle

- Oyang 19 Automatic Non Woven Box Bag Making Machine with Handle Online

- Oyang 18 Automatic Non Woven Leader Box Bag Making Machine with Handle Online

- Oyang 16S Automatic Non Woven Box Bag Making Machine with Handle Online

- XC700-800 Automatic Non Woven 3 in 1 Bag Making Machine with Handle Online

- B700-800 Automatic Non Woven 5 in 1 Bag Making Machine without Handle

- TYM1300 Non Woven Hot Foil Roll to Roll Stamping Machine

- OYANG16 M1100-1800 High Speed Coating and Lamination Machine

- Paper Bag Making Machine

- TECH 18 400S Intelligent Bag Making Machine with Twisted Handle

- High Speed Fix Size Paper Bag Machine

- Automatic Roll-fed Twist Rope Paper Bag Machine Series (with Online Handle)

- Semi-Automatic Roll-fed Paper Bag Machine (Without Handle)

- Roll-fed Sharp Bottom Paper Bag Machine (V-Bottom)

- ONL-SL Slitting Machine

- Automatic Flat Paper Handle Pasting Machine

- Automatic Round Rope Paper Handle Pasting Machine

- Double Station Twisted Paper Rope Machine

- Paper Rope Rewinding Machine

- Flexographic Printing Machine

- Rotogravure Printing Machine

- Screen Printing Machine

- Non Woven Bag Making Machine

- Contact Us

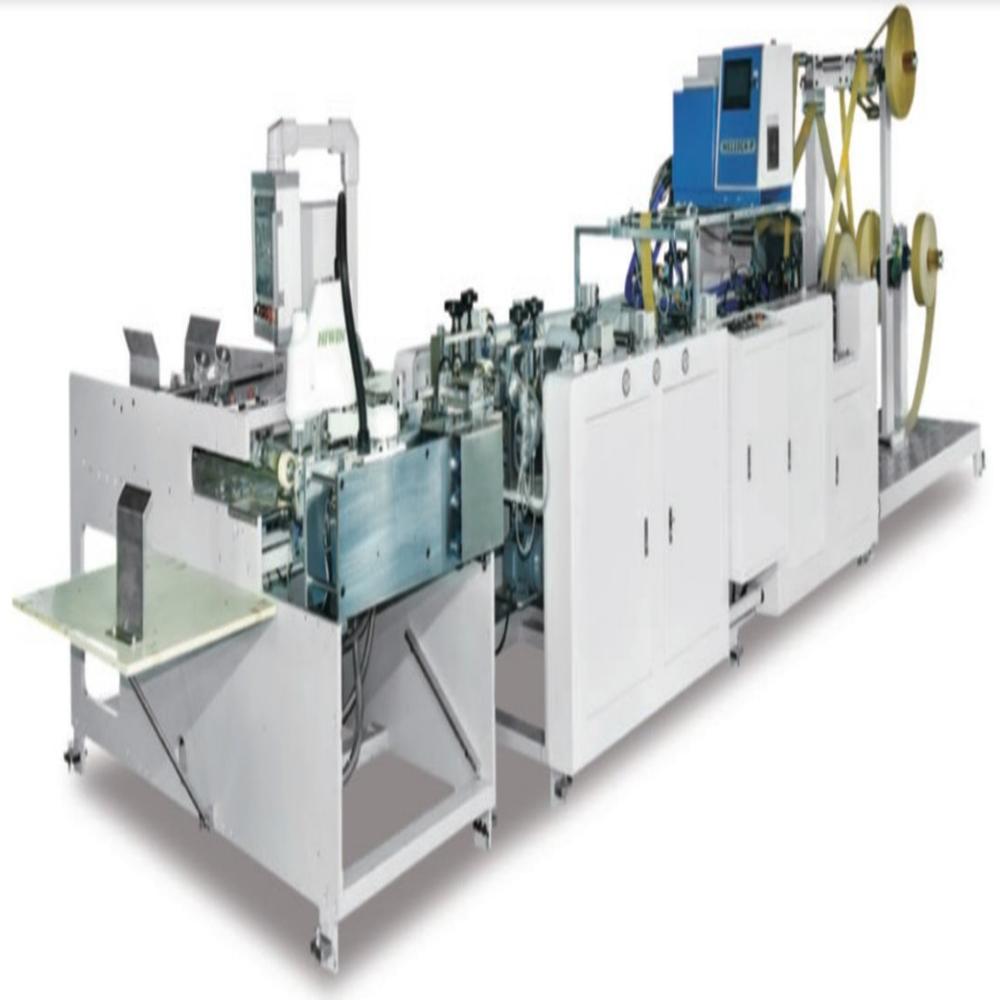

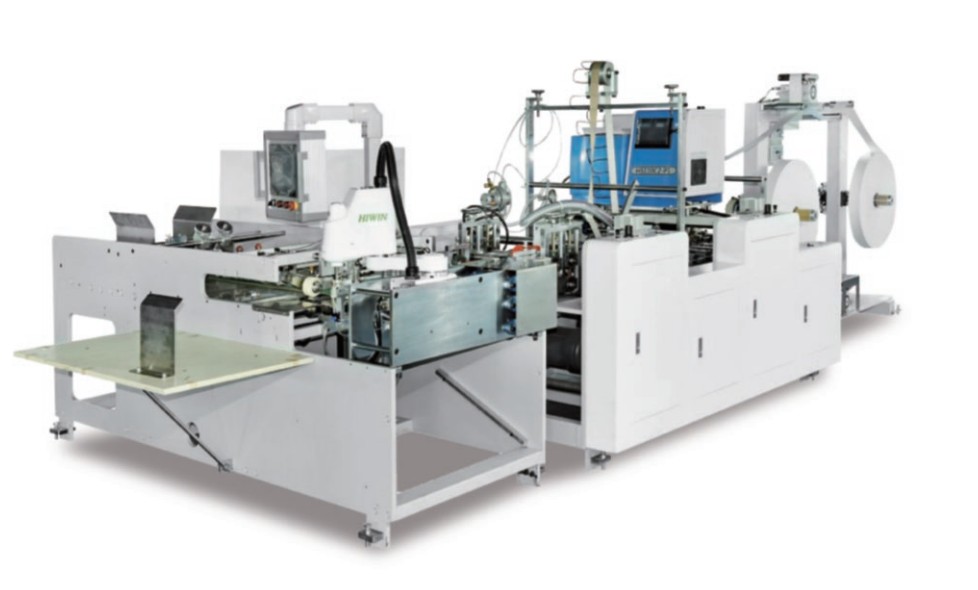

Automatic Round Rope Paper Handle Pasting Machine

5500000.0 INR/Piece

Product Details:

- Product Type Paper Bag

- General Use Paper Bag

- Weight (kg) 2000 Kilograms (kg)

- Automatic Grade Semi Automatic

- Drive Type Manual

- Bag Type Shopping Bag

- Computerized Yes

- Click to view more

X

Automatic Round Rope Paper Handle Pasting Machine Price And Quantity

- 1 Piece

- 5500000.0 INR/Piece

Automatic Round Rope Paper Handle Pasting Machine Product Specifications

- Shopping Bag

- Paper Bag

- 380 Volt (v)

- Paper Bag

- 380 Volt (v)

- Manual

- Yes

- Yes

- Semi Automatic

- Paper

- 1 Year

- 550 Millimeter (mm)

- 2000 Kilograms (kg)

Automatic Round Rope Paper Handle Pasting Machine Trade Information

- Cheque

- 1 Piece Per Day

- 40 Days

- No

- Free samples are available

- All India

Product Description

This machine is engineered to work with a paper bag making line, producing round rope paper handles and automatically gluing and attaching them to paper bags. Its ideal for manufacturers of shopping bags, gift bags, kraft bags, etc., who want high efficiency and reduced labor costs.Key Functions & Capabilities

Automated Handle Production and Attachment

-

Produces round rope paper handles from paper rolls.

-

Applies (pastes) them directly onto bags in line with your bag production sequence, without manual intervention.

High Efficiency

-

Production capacity up to ~10,000 handle pairs per hour (~166 per minute).

-

Ideal for medium-to-large bag manufacturing setups seeking high throughput.

Inline Integration

-

Designed to integrate smoothly with Oyang or other paper bag forming machines, making the entire production seamless and continuous.

Adjustable Dimensions

-

Handle length and rope spacing setups can be customized within typical ranges (e.g., 152190 mm handles, 7595 mm spacing).

| Parameter | Details |

|---|---|

| Brand | Oyang |

| Type | Automatic Paper Handle Making & Pasting Machine (Inline) |

| Paper Roll Core Diameter | 76 mm (3) |

| Max Paper Roll Diameter | 1000 mm |

| Production Speed | ~10,000 pairs/hour ( 166 pairs/min) |

| Power Requirements | 380 V (industrial standard) |

| Total Power Consumption | ~7.8 kW |

| Machine Weight | ~1500 kg |

| Overall Dimension (LWH) | ~4000 1300 1500 mm |

| Paper Handle Length (Optional) | 152 190 mm |

| Paper Rope Handle Spacing (Optional) | 75 95 mm |

| Paper Width (for handles) | 30 / 40 mm |

| Paper Rope Diameter | ~3.0 4.0 mm |

| Glue Type | Hot-melt glue |

Efficient Handle Pasting Technology

Engineered for speed and precision, this paste machine is outfitted with computerized controls and photoelectric correction for consistent placement of round rope paper handles. Its semi-automatic design bridges manual oversight and automated accuracy, ensuring each bag is professionally finished.

Robust and Reliable Design

With a solid structure weighing 2000 kg, this machine accommodates a bag length up to 550 mm. The heavy-duty build ensures stability during high-volume operations, making it a dependable choice for paper bag production units across India.

FAQ's of Automatic Round Rope Paper Handle Pasting Machine:

Q: How does the Automatic Round Rope Paper Handle Pasting Machine operate?

A: This machine utilizes semi-automatic functions with computerized controls and photoelectric correction, allowing for efficient and precise pasting of round rope handles onto paper shopping bags. Operators manually feed materials, while the system automates handle placement and adhesion.Q: What types of bags can be produced with this machine?

A: The machine is specifically designed for producing paper shopping bags, accommodating bag lengths up to 550 mm. It is suitable for a variety of paper bag applications commonly used in retail and packaging industries.Q: When should this machine be used in the bag manufacturing process?

A: It is best employed after the main body of the paper bag is formed, serving as the handle-pasting stage before final packaging. This ensures that handles are securely attached to each bag prior to distribution.Q: Where is this machine typically installed and used?

A: This pasting machine is ideal for installation in industrial paper bag manufacturing facilities, especially those located in India, requiring efficient production of shopping bags with sturdy handles.Q: What is the benefit of photoelectric correction in this machine?

A: Photoelectric correction enhances the accuracy of handle placement, significantly reducing alignment errors and waste. This technology ensures every bag meets consistent quality standards.Q: How does the warranty benefit users of the machine?

A: A one-year warranty provides users with assurance of product performance and access to support or parts replacement from trusted Indian manufacturers or suppliers, minimizing downtime and operational risks.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese