- Home Page

- Company Profile

-

Our Products

- Non Woven Bag Making Machine

- Leader Teach 26 Automatic Non Woven Box Bag Making Machine with Online Handle

- Oyang 19 Automatic Non Woven Box Bag Making Machine with Handle Online

- Oyang 18 Automatic Non Woven Leader Box Bag Making Machine with Handle Online

- Oyang 16S Automatic Non Woven Box Bag Making Machine with Handle Online

- XC700-800 Automatic Non Woven 3 in 1 Bag Making Machine with Handle Online

- B700-800 Automatic Non Woven 5 in 1 Bag Making Machine without Handle

- TYM1300 Non Woven Hot Foil Roll to Roll Stamping Machine

- OYANG16 M1100-1800 High Speed Coating and Lamination Machine

- Paper Bag Making Machine

- TECH 18 400S Intelligent Bag Making Machine with Twisted Handle

- High Speed Fix Size Paper Bag Machine

- Automatic Roll-fed Twist Rope Paper Bag Machine Series (with Online Handle)

- Semi-Automatic Roll-fed Paper Bag Machine (Without Handle)

- Roll-fed Sharp Bottom Paper Bag Machine (V-Bottom)

- ONL-SL Slitting Machine

- Automatic Flat Paper Handle Pasting Machine

- Automatic Round Rope Paper Handle Pasting Machine

- Double Station Twisted Paper Rope Machine

- Paper Rope Rewinding Machine

- Flexographic Printing Machine

- Rotogravure Printing Machine

- Screen Printing Machine

- Non Woven Bag Making Machine

- Contact Us

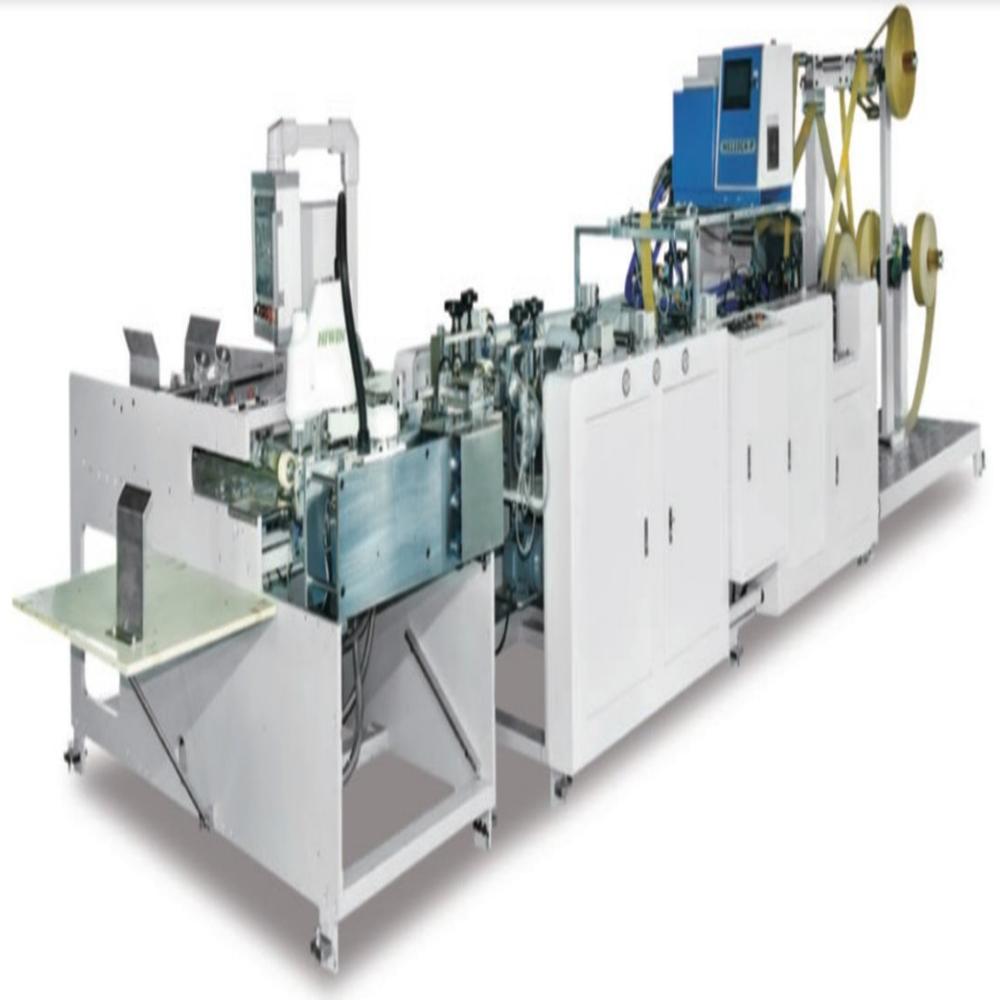

Semi-Automatic Roll-fed Paper Bag Machine (Without Handle)

6000000.0 INR/Piece

Product Details:

- Product Type Paper Bag

- General Use Paper Bag

- Weight (kg) 6000 Kilograms (kg)

- Automatic Grade Automatic

- Drive Type Electric

- Bag Type Shopping Bag

- Computerized Yes

- Click to view more

X

Semi-Automatic Roll-fed Paper Bag Machine (Without Handle) Price And Quantity

- 1 Piece

- 6000000.0 INR/Piece

Semi-Automatic Roll-fed Paper Bag Machine (Without Handle) Product Specifications

- 8.6x2.6x1.9 Meter (m)

- Yes

- Paper Bag

- 380 Volt (v)

- Shopping Bag

- Automatic

- 1 Year

- Yes

- Electric

- Paper Bag

- 6000 Kilograms (kg)

- 380 Volt (v)

- Paper

Semi-Automatic Roll-fed Paper Bag Machine (Without Handle) Trade Information

- Cheque

- 1 Piece Per Month

- 60 Days

- No

- All India

Product Description

A semiautomatic rollfed paper bag machine (without handle) is a production machine that converts continuous paper rolls into finished paper bags without handles. Unlike fully automatic systems, some tasks (like stacking bags, applying additional gluing, or manual inspection) may require human intervention, but the bulk of the forming process is mechanized.| Specification | Typical Range / Details |

|---|---|

| Machine Type | SemiAutomatic RollFed Paper Bag Machine (No Handle) |

| Bag Type Produced | Square / Flat Bottom Paper Bags (without handles) |

| Paper Roll Width | ~2901670mm (modeldependent) |

| Max Roll Diameter | 1500mm |

| Paper Thickness | ~45150g/m (varies by model) |

| Bag Width (W) | ~80560mm |

| Bag Length (L) | ~190770mm |

| Bottom Width (H) | ~50260mm |

| Production Speed | ~150280pcs/min (depends on size & model) |

| Power Supply | ~380V / 3phase (common industrial) |

| Machine Power | ~8kW25kW (model & configuration) |

| Machine Weight | ~560013000kg |

| Machine Footprint | ~8.613m (Length) ~2.6m (Width) ~1.92.0m (Height) |

| Automation Grade | SemiAutomatic (some manual involvement) |

Efficient Paper Bag Production

This machine specializes in creating paper shopping bags without handles, making it perfect for retail and local businesses. Its semi-automatic operation combines speed with minimal manual supervision. With photoelectric correction and computerized control, consistency in bag dimension and quality is ensured, catering to large-scale manufacturing needs.

User-Friendly Operation with Robust Design

Weighing 6000 kg and featuring an easy-to-navigate computerized interface, this machine is built for durability and straightforward use. Its electric drive operates on 380V, making it energy-efficient and compatible with industrial power supplies in India. The intuitive control system allows for streamlined settings and hassle-free maintenance.

FAQ's of Semi-Automatic Roll-fed Paper Bag Machine (Without Handle):

Q: How does the Semi-Automatic Roll-fed Paper Bag Machine operate?

A: This machine operates by taking rolls of paper, automatically feeding them into the system, and precisely cutting and forming them into shopping bags. The photoelectric correction system ensures accuracy throughout the process, with computerized controls allowing customization and consistent output.Q: What types of bags can be produced with this machine?

A: It is designed specifically for manufacturing paper shopping bags without handles, suitable for groceries, boutiques, and other retail applications.Q: When is routine maintenance required for optimal performance?

A: Routine maintenance is recommended every few months, depending on usage. Regular checks include inspecting the electrical system, ensuring rollers are clean, and lubricating moving parts to maintain consistent operation.Q: Where is this paper bag machine commonly used?

A: It is widely used in manufacturing units, small to medium-sized businesses, and packaging suppliers across India seeking efficient paper bag production solutions.Q: What is the typical process for producing paper bags with this machine?

A: The process begins with loading paper rolls, which are then fed into the machine. The machine cuts, folds, and forms the paper into bags, all controlled by computerized monitoring. The bags are finally collected at the output section, ready for packing or distribution.Q: How can businesses benefit from using this paper bag machine?

A: Businesses gain from enhanced productivity, reduced labor costs, and consistent quality in their bag-making operations. Its reliable performance and low maintenance needs make it a cost-effective investment.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Call Me Free

Call Me Free