- Home Page

- Company Profile

-

Our Products

- Non Woven Bag Making Machine

- Leader Teach 26 Automatic Non Woven Box Bag Making Machine with Online Handle

- Oyang 19 Automatic Non Woven Box Bag Making Machine with Handle Online

- Oyang 18 Automatic Non Woven Leader Box Bag Making Machine with Handle Online

- Oyang 16S Automatic Non Woven Box Bag Making Machine with Handle Online

- XC700-800 Automatic Non Woven 3 in 1 Bag Making Machine with Handle Online

- B700-800 Automatic Non Woven 5 in 1 Bag Making Machine without Handle

- TYM1300 Non Woven Hot Foil Roll to Roll Stamping Machine

- OYANG16 M1100-1800 High Speed Coating and Lamination Machine

- Paper Bag Making Machine

- TECH 18 400S Intelligent Bag Making Machine with Twisted Handle

- High Speed Fix Size Paper Bag Machine

- Automatic Roll-fed Twist Rope Paper Bag Machine Series (with Online Handle)

- Semi-Automatic Roll-fed Paper Bag Machine (Without Handle)

- Roll-fed Sharp Bottom Paper Bag Machine (V-Bottom)

- ONL-SL Slitting Machine

- Automatic Flat Paper Handle Pasting Machine

- Automatic Round Rope Paper Handle Pasting Machine

- Double Station Twisted Paper Rope Machine

- Paper Rope Rewinding Machine

- Flexographic Printing Machine

- Rotogravure Printing Machine

- Screen Printing Machine

- Non Woven Bag Making Machine

- Contact Us

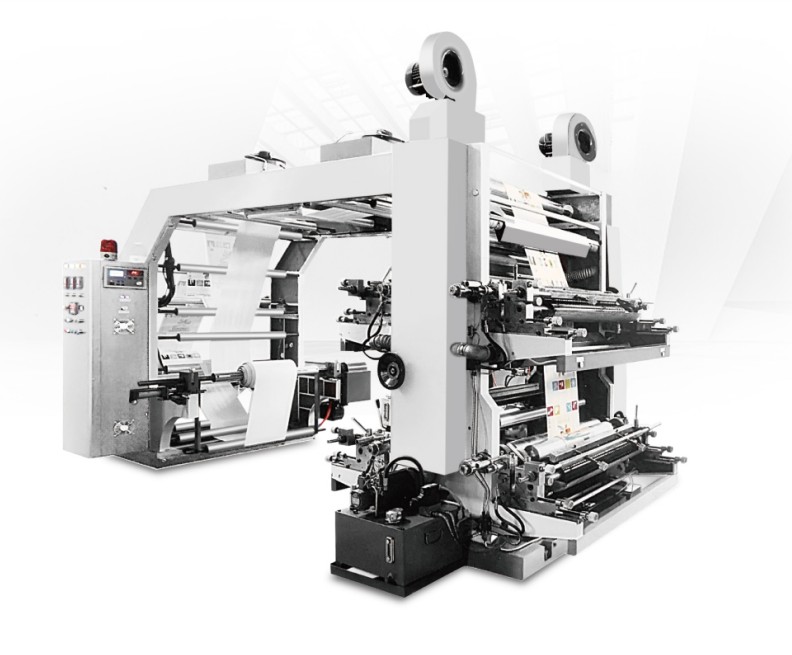

YTB Series Stack type High Speed Flexographic Printing Machine

4000000.0 INR/Piece

Product Details:

- Type Paper Bag

- Material Craft Paper

- Capacity 2400 Pcs/hr

- Printing Speed 40 m2/hr

- Computerized Yes

- Automatic Grade Manual

- Plate Type Other

- Click to view more

X

YTB Series Stack type High Speed Flexographic Printing Machine Price And Quantity

- 4000000.0 INR/Piece

- 1 Piece

YTB Series Stack type High Speed Flexographic Printing Machine Product Specifications

- 380v Volt (v)

- Other

- PLC Control

- Paper Bag

- Yes

- Other

- 450mm Millimeter (mm)

- Other

- 2400 Pcs/hr

- 20x8x5.5 Foot (ft)

- 40 m2/hr

- 1400 Kilograms (kg)

- Manual

- Other

- Craft Paper

YTB Series Stack type High Speed Flexographic Printing Machine Trade Information

- 40 Days

Product Description

Key Features

StackType Flexo Configuration

-

Multiple stacked printing stations allow 26 colors, enabling multicolor printing on web materials.

-

Flexo printing technology with rubber or photopolymer plates offers fast, highthroughput printing suitable for packaging and bag surfaces.

High Production Speed

-

Designed for 80100m/min printing speed, enabling high output for medium to large volumes.

-

The stack design promotes efficient rolltoroll operation, ideal for continuous production runs.

Accurate Registration

-

Register precision up to 0.3mm helps ensure consistent color alignment across repeats, essential for multicolor graphic quality.

Material Compatibility

-

Suitable for paper rolls, nonwoven materials, laminated films, and similar substrates used in consumer and industrial packaging.

-

Typically uses waterbased or solvent inks depending on production requirements.

Versatile Plate & Repeat Options

-

Support for a wide range of printing plate thicknesses and print repeat lengths, making it adaptable to varied print jobs and designs.

| Specification | Typical Value / Range |

|---|---|

| Model Examples | YTB61200, ZYT41400, YT41000 (varies by size & color count) |

| Web / Material Feeding Width | 800mm, 1000mm, 1200mm, 1300mm, 1400mm (configurable) |

| Max Printing Width | 760mm 1360mm (depending on model) |

| Printing Colors | 2color, 4color, 6color options (stack type) |

| Printing Speed | 80100m/min (highspeed rolltoroll) |

| Register Precision | 0.3mm (accurate print alignment) |

| Plate Thickness Options | 1.14mm, 1.7mm, 2.28mm, 2.84mm, 3.94mm (customizable) |

| Printing Length (Repeat) | Standard ~400mm; optional 3001000mm |

| Max Unwind/Rewind Diameter | ~1000mm (standard) |

| Heating Method | Electric heating for drying printed web |

Advanced PLC Control for Precision Printing

The YTB Series utilizes a sophisticated PLC control system, ensuring seamless operation and superior print quality for craft paper applications. This automated precision translates into minimal errors and optimized print consistency, ideal for demanding production environments.

Optimized for High-Speed Paper Bag Manufacturing

Engineered specifically for paper bag printing, this flexographic machine enables manufacturers to achieve rapid output of up to 2,400 pieces per hour. Its design caters to varied paper widths (up to 450mm), ensuring flexibility and quality for different bag sizes and formats.

FAQ's of YTB Series Stack type High Speed Flexographic Printing Machine:

Q: How does the PLC control system enhance the YTB Series printing process?

A: The PLC control system automates key operational functions, resulting in precise registration, improved workflow, and consistent print quality during high-speed production. This reduces manual intervention and enhances the efficiency of paper bag printing.Q: What types of materials can the machine print on, and what is its width capacity?

A: The machine is tailored for kraft paper, commonly used for paper bag manufacturing, and can accommodate materials up to 450mm in width, allowing for versatile production options.Q: When should you consider using the YTB Series Stack type flexographic printer?

A: This machine is ideal for businesses requiring fast, reliable, and high-volume printing on paper bags, particularly in industries such as retail packaging, food delivery, or branding.Q: Where is the YTB Series flexographic printing machine typically installed or used?

A: It is mainly installed in factories, industrial print shops, and large-scale manufacturing units across India that specialize in producing craft paper bags.Q: What is the process for setting up and operating this flexographic printing machine?

A: Setup involves feeding the kraft paper, calibrating the PLC control parameters, loading ink, and selecting the appropriate print settings. Operators guide the process, and the machine's automatic features ensure consistent and efficient printing.Q: How is the print speed and capacity beneficial to manufacturers?

A: With a print speed of 40 m2/hr and a capacity of 2,400 pieces per hour, the machine significantly boosts productivity, allowing manufacturers to meet large orders quickly while maintaining high print standards.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Call Me Free

Call Me Free